- General Details

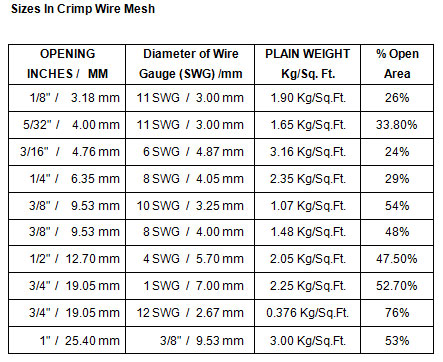

- Sizes In Crimp Wire Mesh

- Inquiry

|

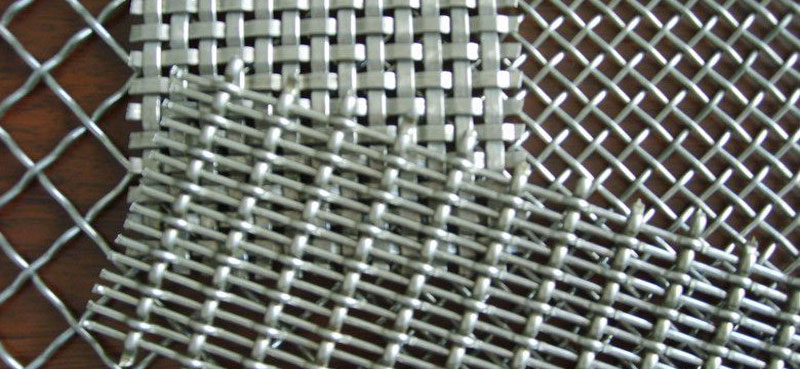

Crimped Wire Cloth The idea to crimp the wire mesh is to make the opening of screen more accurate and tougher. This product works where sizing or aperture accuracy is important. There are different types of crimped sieves which are manufactured in different styles such as

Double Crimp: The pattern of plain weave in which warp and weft wires are passed over and under of each warp and weft wires in each successive rows.

Intermediate Crimp: There is an extra crimp wire bend in warp and weft wires between the point of intersection. This kind of crimp is used where large open area is required. Light wires are locked and tightened to produce rigidity in the sieve.

Lock Crimp: The crimping is done in such a manner that the weft and warp wires pass each other at the point of intersection. The deep crimping locks the wire assuring no movement of wire.

Flat Top Crimp: This crimp style gives a smooth surface to improve the material flow. The lock maintains the opening even when product fixed at high speed ensuring strength.

Triple Shot Crimp: This is used where the screening material tends to clog the opening and blinds the cloth. The wires are hold properly and vibration keeps the opening clear.

USES are numerous which includes filtering, sizing, grading, separating in the industries such as construction, coal mining where it is used as vibratory screens. |