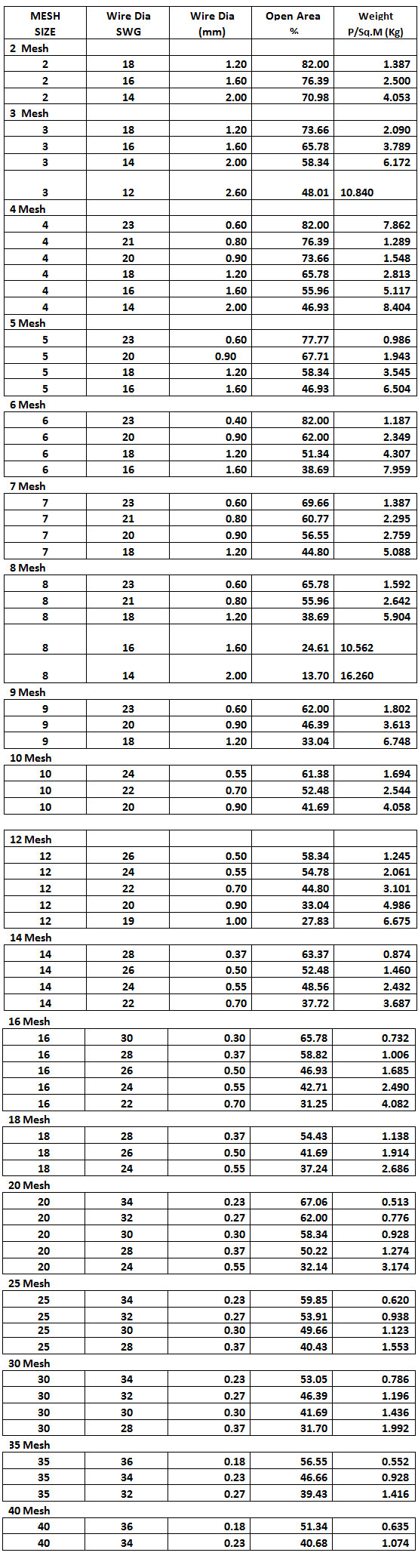

- General Details

- Sizes In SS Plain Wire Mesh

- Inquiry

|

Wire Mesh

The connection between wire mesh is as old as the company, as it was the first business of the family. The business was started by the installation of one loom manufacturing coarse meshes, but with the gradual growth, company have made remarkable advancement in the field, further by entering into fine meshes in the materials such as plain carbon steel (annealed/galvanized), stainless steels, brass and copper. Today we are on the list of varied companies serving its general purpose of filtration, screening and at place where strengthening is required. The terminology of mesh screens used does include important criteria of the selection of material with effect of its environment, wire diameter, aperture, width and length.

When Ordering the Terminology used is as Follows:

|

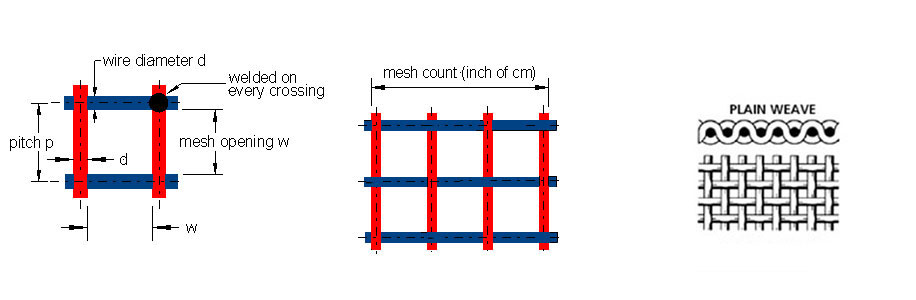

1. Mesh: The no of square holes in 1 linear inch is termed as mesh.

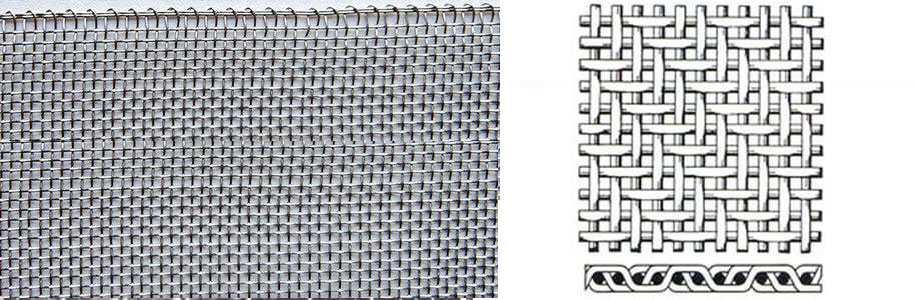

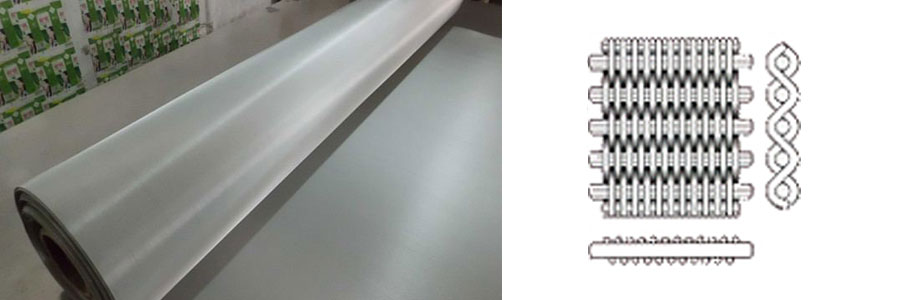

Type of Weaves: Wire mesh has been manufactured in different kinds of weaves. 1. Plain Weave: This is the most common type of weave. In this weave the diameter of warp and weft wires are same. The weft wire passes alternately over and under each warp wire and each warp wire passes alternately over each weft wire.

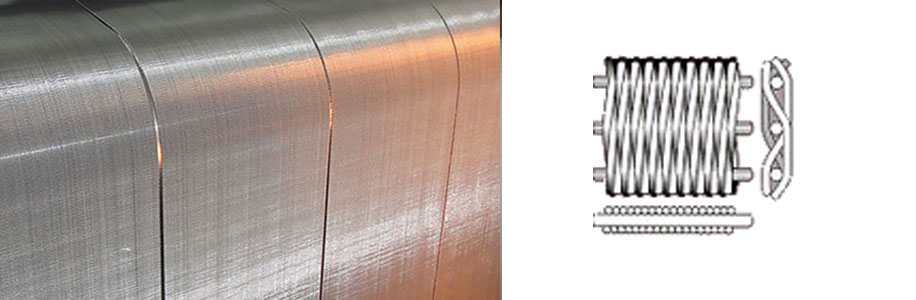

2. Twill Weave: In this type of weave, wire used are heavier then the standard wire diameter used in the mesh. The terminology of this weave is that two successive warp wires passes over two weft wires alternately and two weft wires passes over two warp wires successively in a staggered.

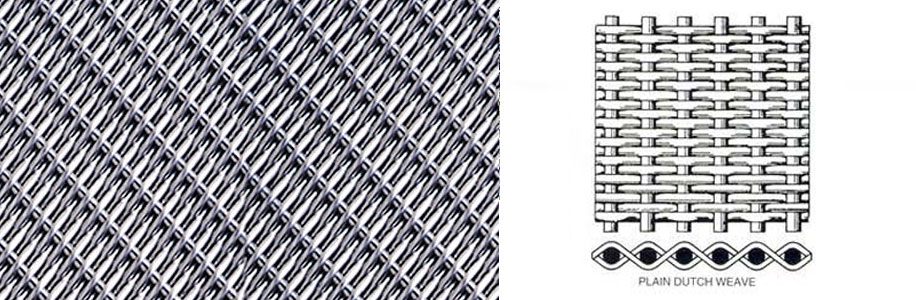

3. Plain Dutch Weave: In this type of weave, wire used are heavier then the standard wire diameter used in the mesh. The terminology of this weave is that two successive warp wires passes over two weft wires alternately and two weft wires passes over two warp wires successively in a staggered.

4. Reverse Plain Dutch Weave (RPD): It’s the opposite of Plain Dutch weave where the weft wire is heavier then the warp wire. Strongest filter weave because of semi rectangular opening. As this has an accurate and uniform pore size so it is exceptionally easy to clean.

5. Reverse Twill Dutch(RTW)/Weave (Hollander Weave): Each wire passes over two and then under two wires. As far as the thickness of wire is concerned the terminology is same that of Plain Dutch. Tighter weave and more refine filtration then plain Dutch. Flow rate is extremely torturous thus allowing excellent particle retention.

Metals & Alloys

|

The weight of the material been calculated on the basis of following,

Multiplying factor with the numeric weight of the material. Steel is taken as reference material.

. Aluminum 34.17%

. Brass (70/30) 108.73%

. Copper 113.35%

. Inconel (600) 108.92%.

. Monel 112.20%

. Plain Steel 100%

. Stainless Steel (18-8) 100.98%