- General Details

- How to Order

- Inquiry

|

Perforated Metal

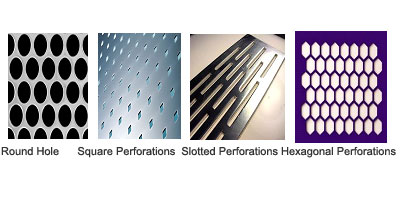

Afzal Machinery Stores (AMS) has been involved in perforated business since 1997. In the span of 15 years the company has developed wide range of perforated sheet in round, square, hexagonal, diamond, oval, rectangular(slot) and eclipse shape manufactured under the umbrella of highly qualified technical staff working on heavily equipped plant. Different patterns in perforations can be offered at the economical cost with different options. It is economical to choose from the available cost as new pattern can be manufactured with additional cost.

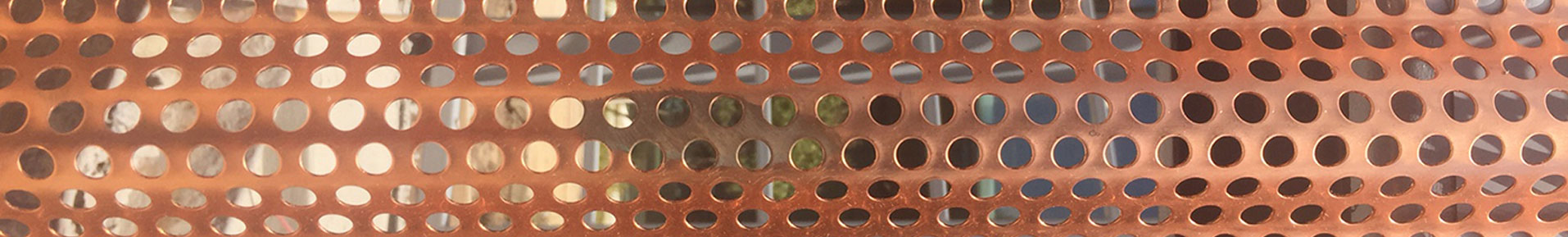

Types of Perforations: Round Hole Perforations

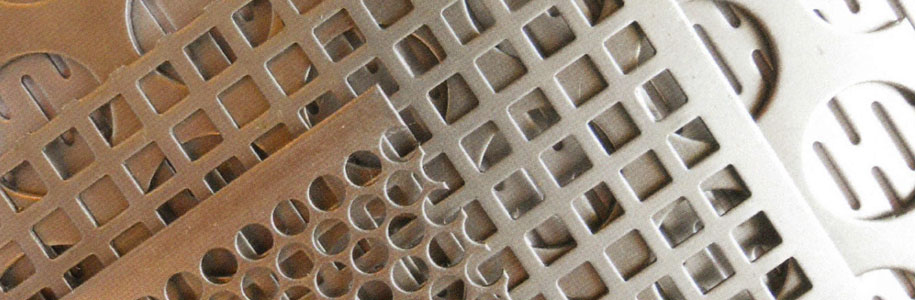

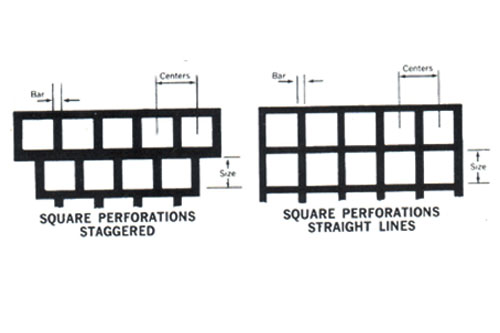

Square Perforations:

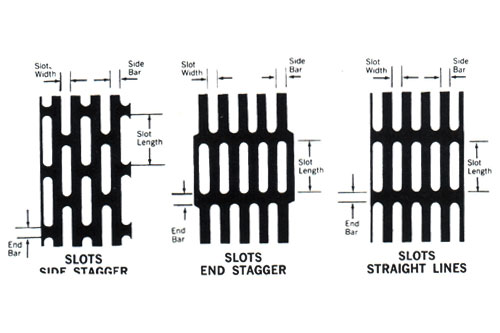

Slotted Hole Perforations:

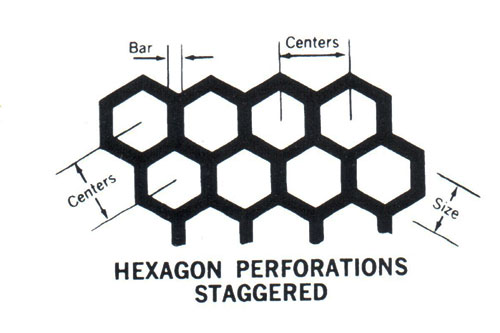

Hexagonal Perforations:

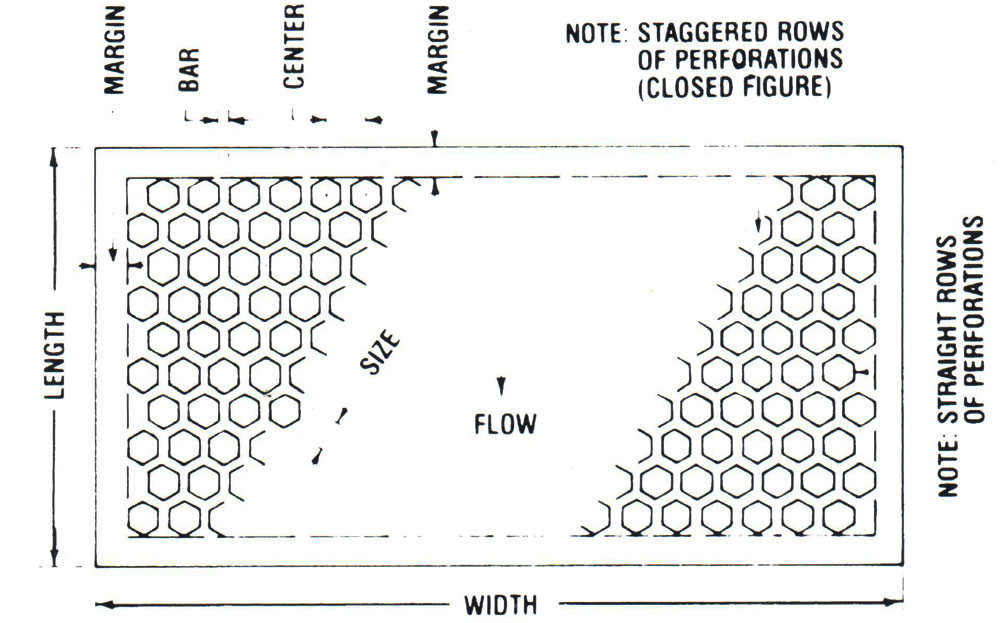

Terminology Used In Perforated Metal & How to Order: This includes diameter of the round hole, slot size (which includes square, rectangular), eclipse, hexagonal.

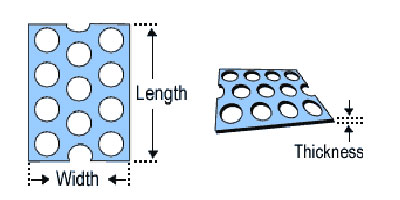

Thickness and Size: The thickness of the sheet needs to be perforated whereas the size includes the length and width of the sheet. These elements are required for the determination of the weight of sheet.

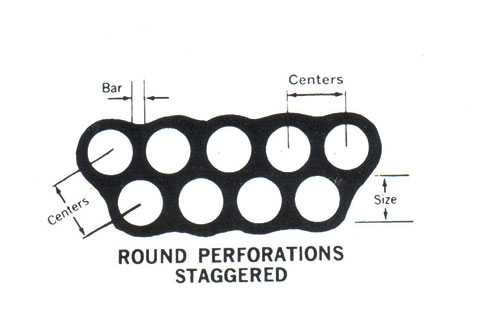

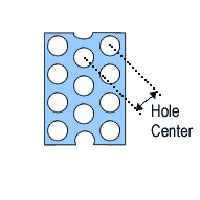

Pitch: The center to center distance between of two holes. Slot Perforations have two pitch dimensions one is at right angles and other is parallel to the longitudinal axis of the slot.

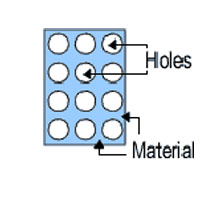

Open Area: The total area of the holes divided by the total area of the sheet is the open area. The value is in percentage which is the result of design, dimension and distribution in perforation. When the holes are punched in a sheet the stresses developed creates distortion. The higher the open area the more will be the distortion created. Reaching the maximum of open area reduces the strength and rigidity of the material.

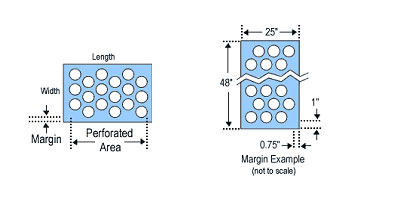

Margins: The blank area along the edges of the sheet. Dimensions should be marked indicating the width and the length of margins along the four sides. It should be noted that greater the width of the margin greater will be the distortion in the straightness of the sheet. It is recommended to have minimum or no end margins and minimum side margins.

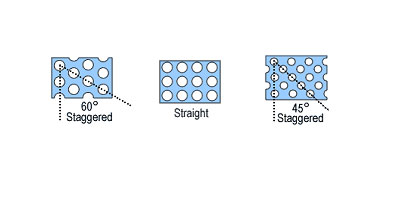

Patterns and Directions: Perforated meshes are manufactured in straight and staggered directions at angles of 60 deg and 45 deg normally used. Round, square, hexagonal, rectangular (slots with round end and square ends) and eclipse, all these patterns are derived according to the customer use.

Orientation in Perforation:

The direction of the screens is very important as it is the direction across which the product travels across the plate. Best results are achieved in staggered pattern arrangements in the direction of the flow. In this regard size of the aperture is of great importance.

|