- General Details

- How to Order EMM

- Inquiry

|

Expended Metal

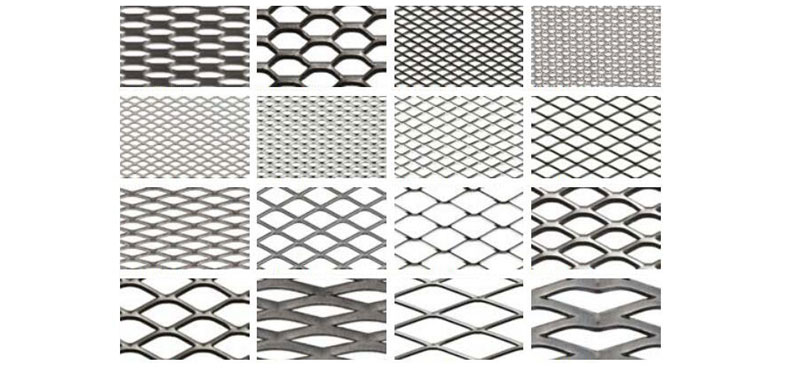

AMS has been involved in the manufacturing of Expanded Metal Mesh (EMM) since 1980’s and offer in four different categories as per customer requirement:

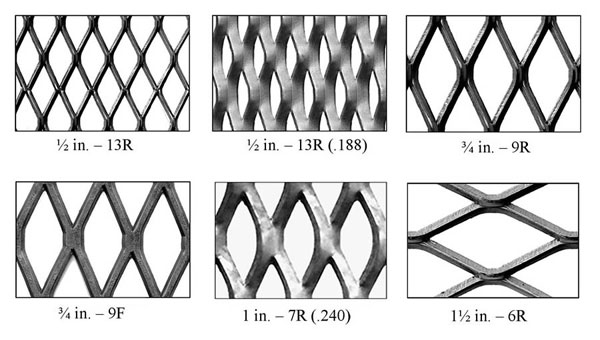

1. Plain Expanded Metal

EMM can be manufactured in the form of coils or sheets or in panels as per need of the customer.

|

|

Material Used:

Manufacturing Process and Comparison with Wire Mesh: |

Terminology and How to Order EMM:

-

1. Determining the diamond size and shape best suited for the given application.

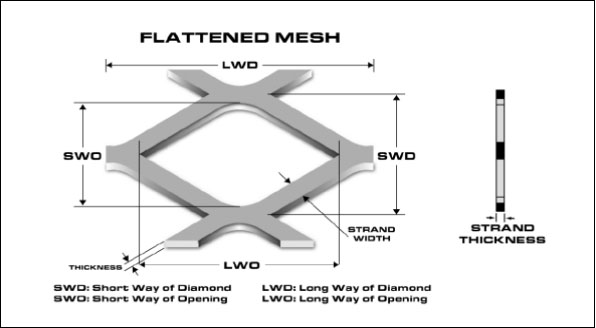

2. In order to go in detail for the diamond size following parameters are to be used

a. SWM = Short way Mesh

b. LWM = Long Way Mesh

c. Strand Width = Cutting of the material as per requirement of strength demanded from the material used under Impact and effecting in the increase or decrease in length.

d. Strand Thickness = Thickness of the sheet or Plate

All the above parameters are the constituents in determining the open area of the material.

Orientation in EMM is important phenomenon as it solely depends on the application. It is very important to remember that the width of the metal is always measured in the direction of short way length whereas the length is measured in the long way direction of the diamond mesh.

EMM are widely used material in variety of applications due to been cheaper as compared to its competitor products. Dominant in the areas such as Automotive air and oil filters, Construction Industry, Cages for Animal Storage, Cement Plants, Speaker Industry, Protective Grills, Cement Industry Guard Rail and many other applications.